The tunnel freezer is a high-efficiency quick freezing machine with relatively simple structure. It is mainly used for quick-freezing processing of pasta, seafood, poultry, vegetables, fruits, dairy products and other foods. Freezing capacity can be 100kg/h-2000kg/h.

The features of tunnel quick freezer

Thermal storage body

-

The bottom plate is assembled by full welding process, which has excellent waterproof and thermal insulation performance.

-

There are maintenance and cleaning channels on both sides of the warehouse body, which is convenient for cleaning and maintenance of equipment;

-

The reservoir body is equipped with a drain outlet, which can drain quickly and not store water;

-

he specially designed sealing strip of the thermal insulation door can effectively block the airflow and prevent the occurrence of cold running.

-

Buried electric heating in the door frame, heating evenly, to ensure that the thermal insulation door does not freeze, and it is easy to open.

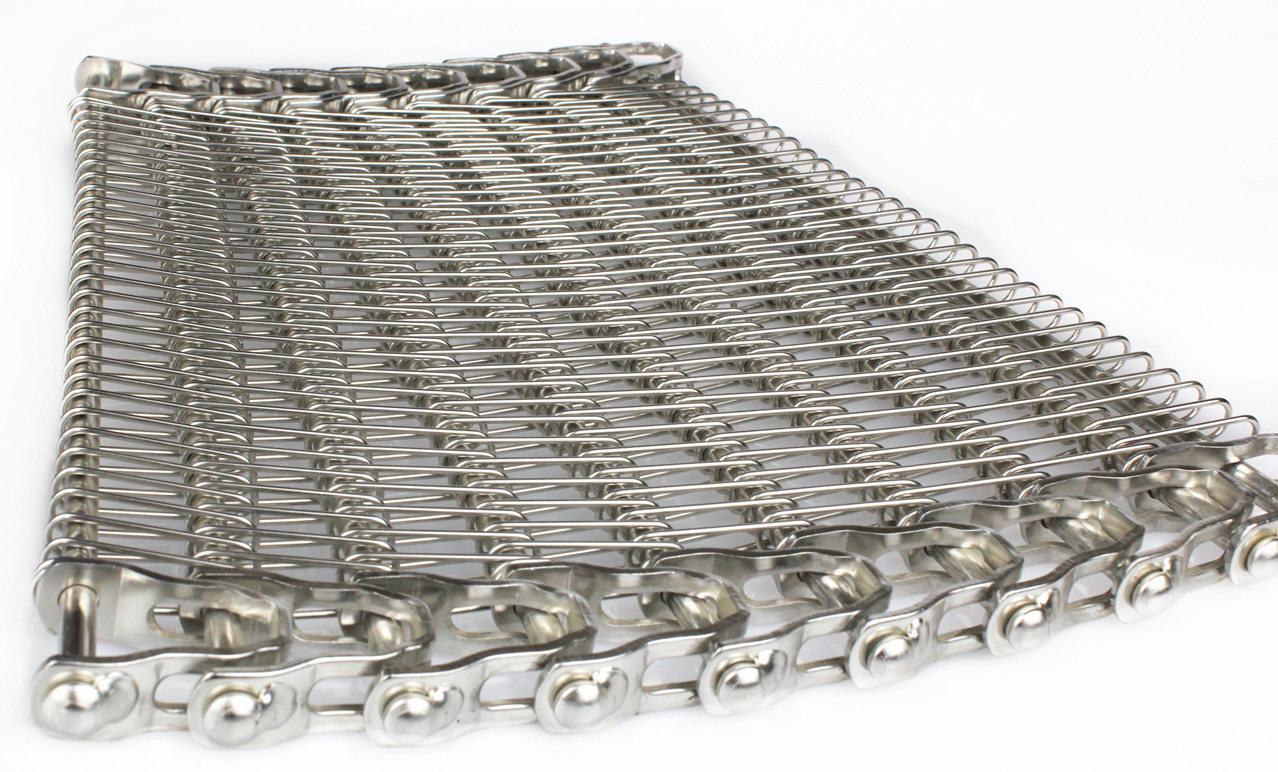

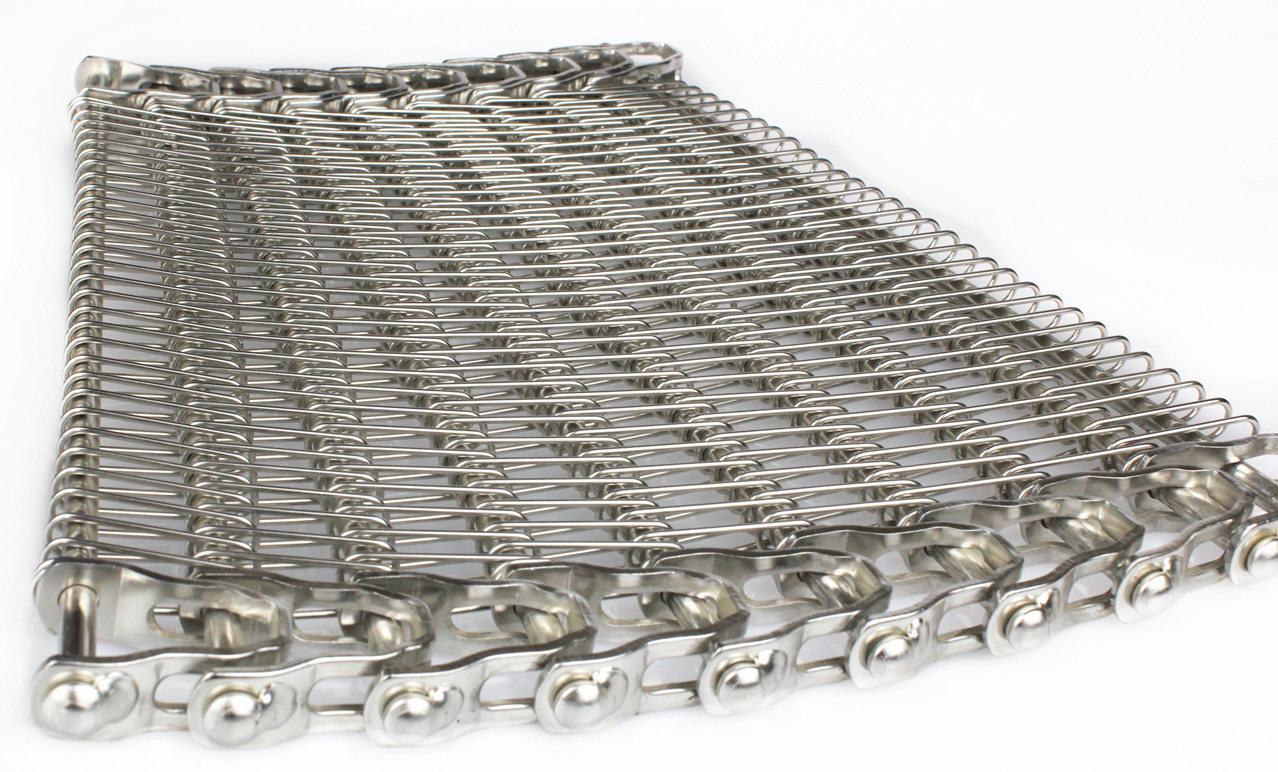

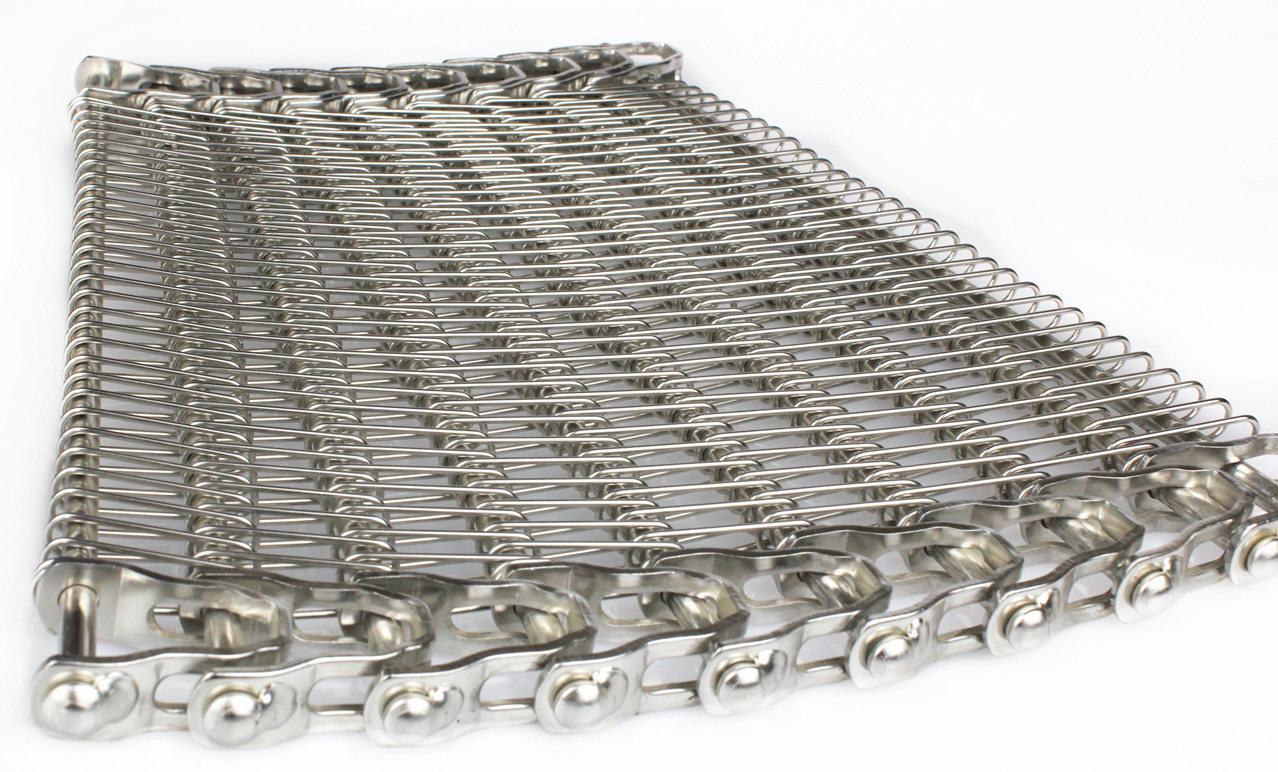

Mesh belt and transmission system

-

Ultra high molecular polyethylene precision casting mesh belt support bars are held smoothly, reducing mesh belt wear, and making mesh belts have a longer service life;

-

The mesh belt drive adopts chain drive, which runs smoothly and reliably, ensuring long-term continuous operation of the equipment;

-

The mesh belt at the discharge port adopts a tensioning device, which can easily adjust the tightness of the mesh belt and prevent the mesh belt from deviating and loosening;

-

The transmission sprocket, chain and bearing are all made of stainless steel, which meets the requirements of food hygiene.

-

The mesh belt material is food-grade stainless steel, which is corrosion-resistant, high-strength, and passivated on the outer surface;

Air distribution system

-

The unique "fluidized" air distribution system is designed, which makes the jet flow high, strong and uniform, ensuring the freezing quality of frozen products;

-

Adopt low-noise, high-efficiency centrifugal fan, stable and reliable operation, and can ensure long-term stable operation under low temperature;

Evaporator

-

Advanced and reasonable structure, small flow resistance of refrigerant in the tube, fast freezing speed and good freezing quality;

-

Variable sheet pitch, with the best airflow organization, less frost, can work efficiently and continuously for a long time;

-

Fin production adopts one-time molding process, the contact area between tube and sheet is large, and the heat transfer coefficient is high;

-

The defrosting method adopts the water flushing method, and the water spraying tray spraying water method, the flushing water is more evenly distributed, and the defrosting time is effectively reduced.