| Availability: | |

|---|---|

| Quantity: | |

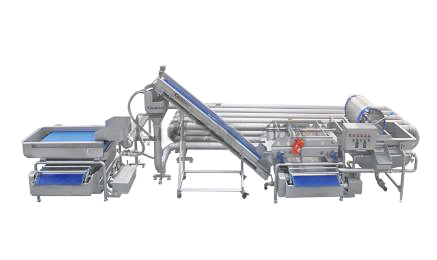

UFEC

| Product Name | Root Vegetable Processing Line |

| Main Material | SUS 304 food grade |

| Function | Vegetable selecting, washing, Peeling, cutting, Dehydrate in continuous |

| Package | In Plywood Case |

| Size | 2170x1140x1800mm |

| Production capacity | 2000-2500kg/h |

| Total power | 1.4KW |

| Voltage | 380V or customized |

| Size | 3450x1280x1900mm |

| Production capacity | 1.5T/h |

| Total power | 2.25KW |

| Voltage | 380V or customized |

| Number of hair rollers | 9 |

| Size | 4000x1420x1170mm |

| Total power | 1.12KW |

| Voltage | 380V or customized |

| Model | H460 | H500 |

| Size | 3300x650x2000mm | 3850x785x1900mm |

| Conveyor belt width | 460mm | 500mm |

| Total power | 0.75KW | 0.37KW |

| Voltage | 380V or customized | |

| Model | CDM1000 | CDM2000 |

| Size | 1200x800x1300mm | 1470x1050x1400mm |

| Production capacity | 1T/h | 2T/h |

| Total power | 1.1KW | 1.5KW |

| Voltage | 380V or customized | |

| Model | SM1500 | SM2500 |

| Size | 4000x1340x1465mm | 5000x1340x1465mm |

| Production capacity | 2T/h | 3T/h |

| Total power | 4.09KW | 7.09KW |

| Voltage | 380V or customized | |

| Dimensions | 9400x3420x2600mm |

| Production capacity | 1.5T/h |

| Total power | 4.9KW |

| Voltage | 380V or customized |

| Dimensions | 5370x1506x2189mm |

| Production capacity | 3T/h |

| Total power | 6.25KW |

| Voltage | 380V or customized |

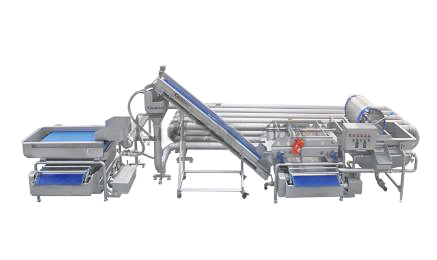

| Product Name | Root Vegetable Processing Line |

| Main Material | SUS 304 food grade |

| Function | Vegetable selecting, washing, Peeling, cutting, Dehydrate in continuous |

| Package | In Plywood Case |

| Size | 2170x1140x1800mm |

| Production capacity | 2000-2500kg/h |

| Total power | 1.4KW |

| Voltage | 380V or customized |

| Size | 3450x1280x1900mm |

| Production capacity | 1.5T/h |

| Total power | 2.25KW |

| Voltage | 380V or customized |

| Number of hair rollers | 9 |

| Size | 4000x1420x1170mm |

| Total power | 1.12KW |

| Voltage | 380V or customized |

| Model | H460 | H500 |

| Size | 3300x650x2000mm | 3850x785x1900mm |

| Conveyor belt width | 460mm | 500mm |

| Total power | 0.75KW | 0.37KW |

| Voltage | 380V or customized | |

| Model | CDM1000 | CDM2000 |

| Size | 1200x800x1300mm | 1470x1050x1400mm |

| Production capacity | 1T/h | 2T/h |

| Total power | 1.1KW | 1.5KW |

| Voltage | 380V or customized | |

| Model | SM1500 | SM2500 |

| Size | 4000x1340x1465mm | 5000x1340x1465mm |

| Production capacity | 2T/h | 3T/h |

| Total power | 4.09KW | 7.09KW |

| Voltage | 380V or customized | |

| Dimensions | 9400x3420x2600mm |

| Production capacity | 1.5T/h |

| Total power | 4.9KW |

| Voltage | 380V or customized |

| Dimensions | 5370x1506x2189mm |

| Production capacity | 3T/h |

| Total power | 6.25KW |

| Voltage | 380V or customized |